This is an article on how to change or

freshen up the interior color of your truck, Blazer, or Suburban using paint

or vinyl dye.

To plan your dye job, you must first determine how you are going apply the

dye. If you have access to a compressor and a paint gun, this is the best

way to go if you plan to dye all your interior pieces. If not, don't

worry...you can still get quality results with spray cans "if" you take the

time to prep everything correctly.

Regardless of how you apply the dye, you will need the vinyl dye and vinyl

prep that goes on before the dye.

Before you start the tear down, you should examine all your existing trim

pieces. Are they worth dying, or should they be replaced? If they are

cracked, deteriorated, or damaged in any way...now is the time to find

replacement pieces. The dye will not hide these blemishes and will

leave you unhappy with the results and lighter in the pocketbook.

Check you dash pad real close (especially by the speaker holes), is it

cracked? What about your door panels & armrest pads? You better

replace them too if you want this job to come out looking good. Once all

this is decided, it's time to move on.

Step #1. The dirty work begins. Remove everything that

you want to dye from your truck. It can be done while still installed,

but it will make a big mess, so take the time to pull everything out now.

Put the screws in zip lock bags and tag them so you remember where they go.

Take your time so you don't cause any damage or lose any parts when removing

all of the items you will be dying.

Step #2. This step may be skipped if you don't have pieces that

have previously been dyed. If any piece has been dyed before, it is best to

strip the old dye off. I found the best way to do this is with cheap

lacquer thinner and paper towels...I would also suggest using gloves that

are chemical proof too. Cheap lacquer thinner is great for removing

old dye, as well as layers of skin from your hands. Trust me on this

one.

Step #3. This is the most important step to achieve quality

results. Every inch of every piece should be thoroughly cleaned.

Even if you have stripped them with lacquer thinner, I would still clean

them with soapy water. This is an "extremely" important step!

Make a solution of dishwashing soap and water. It's a good idea to add

a small amount of ammonia or Mr. Clean to the water to help strip the vinyl

dressing and oil that the plastic emits as it ages is. Wash every

piece front and back with this solution, then rinse with clean water. Now

repeat this process again. Once you have repeated the process dry the

parts completely. Make sure that there is no moisture left anywhere on

the panels. If you can’t blow them dry with compressed air, it might

be best to set them in the sun, or cover them and let them air dry over

night.

Step #4. Prep your pieces with vinyl prep. Read the

instructions and follow them closely. Some preps are designed to dry

completely before the dye is applied, and some suggest you prep then apply

the dye right away. Make sure you read the instructions and follow

them closely.

Step #5. This is the fun part. You finally get to see all

your hard work pay off, but do not rush this step...take your time and put

on nice even coats. Again, read the instructions and follow them

closely. If you are using a spray gun, once you get everything covered

completely you will finish with a final overlap coat to make sure you don’t

have any dry spots or stripping. If you are using spray cans, save a

fresh can to give everything a final coat. This will ensure that

everything is the same color as well as preventing any dry spots or

stripping.

In closing...

If you are using a spray gun, check with your local automotive paint

store for the brand that they carry. They can set you up with the

correct prep and dye and answer any questions you may have. If you are

going to use spray cans, the best brand in my opinion is SEM. It can

be bought through

Eastwood, or ordered online from many supply companies. If you

have taken your time and done this correctly, the end results should like

the pics I have posted below.

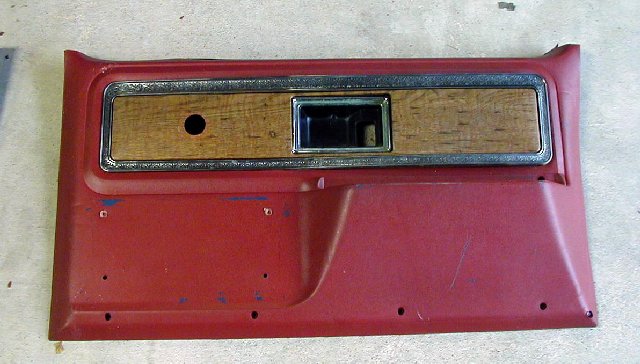

This is the door panel I purchased at a swap meet. While it doesn't

look too bad, the dye was really scratched up and peeling in places.

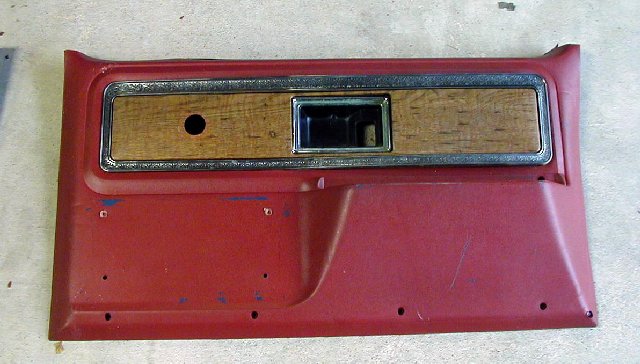

This is after 30-40 minutes of stripping all the old dye off.

Here is a close up "after" shot.

Home